State of art agri implements and garden tools, and Cold drawing facility

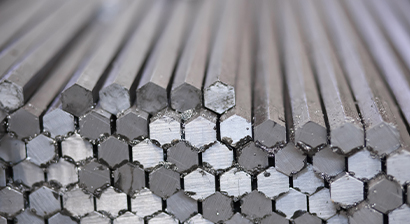

An MS cold drawing unit is an industrial machine used to produce high-quality cold-rolled steel bars or wire rods. The process involves drawing the hot-rolled steel through dies at room temperature to produce bars with a smoother surface finish and improved mechanical properties.

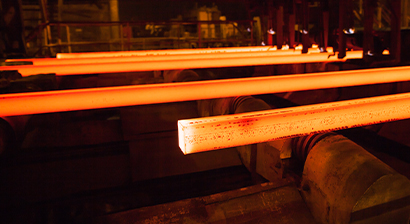

Hot Re Rolling mill for production of section and bars.

A hot rolling mill is a type of industry used in the metalworking to shape, roll, and form metal products such as steel. The process involves heating steel billets above their recrystallization temperature, then passing them through a series of rollers to reduce their thickness and improve their mechanical properties.

Our facility specializes in the production of mild steel (MS) products. We takes heated steel billets or slabs and passes them through a series of rollers to shape and form them into various products such as rods, bars, angles, channels, and beams.

Overall, we put our shelves in important part of the steel industry, as it allows for the production of high-quality, cost-effective mild steel products that are used in a wide range of applications.

Steel billets or slabs are heated to a high temperature in a furnace.

The heated billets or slabs are then sent through a reheating furnace to ensure they are uniformly heated.

The heated billets or slabs are then passed through a series of rollers, which reduce their thickness and shape them into the desired product.

The rolled products are then cooled in a controlled manner to ensure they achieve the desired mechanical properties.

The final product is then inspected, tested, and finished to meet the required specifications.

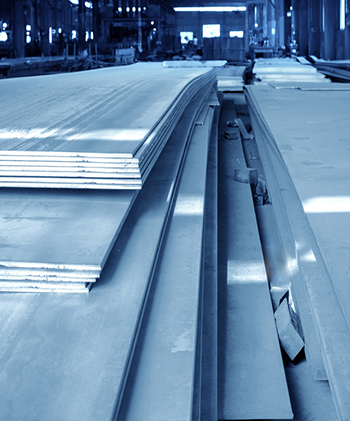

An MS cold drawing unit is an industrial machine used to produce high-quality steel tubes and pipes from hot-rolled steel bars or wire rods. The process involves drawing the hot-rolled steel through a series of dies at room temperature to produce tubes or pipes with a smoother surface finish and improved mechanical properties.

MS cold drawing units are commonly used to produce high-quality steel tubes and pipes for a variety of applications, including automotive, aerospace, construction, and industrial uses. The advantages of using cold-drawn steel products include increased strength, improved surface finish, and tighter dimensional tolerances.

Overall, an MS cold drawing unit is an important part of the steel industry, as it allows for the production of high-quality steel tubes and pipes with excellent mechanical properties and surface finish.

The process begins with the selection of high-quality hot-rolled steel bars or wire rods.

The raw material is cleaned and treated to remove any surface impurities.

The steel bars or wire rods are then annealed to improve their ductility and prepare them for the cold drawing process.

The steel bars or wire rods are drawn through a series of dies, which progressively reduce their diameter and improve their surface finish.

The finished tubes or pipes are cut to the desired length, inspected for quality, and subjected to any necessary surface treatments or coatings.